Sustainable Fabric Wholesale Direct| supplier

GRS Certified cotton recycled polyester blend fabrics

Cut Costs with Eco-Friendly Fabrics!

Better Prices

Same quality as ring-spun at up to 50% lower cost.

Rapid production

20-30 days, from order confirmation to production completion.

Quality Assurance

Certified by GRS, with strict production adhering to ISO and EN standards.

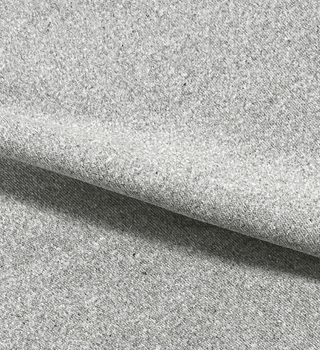

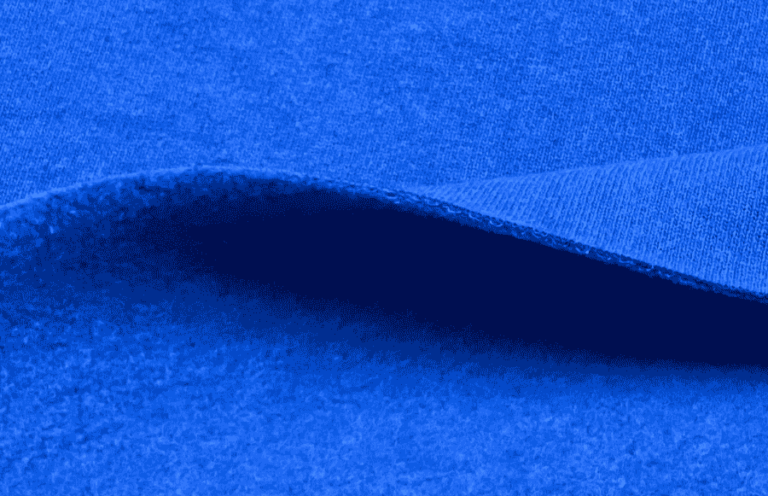

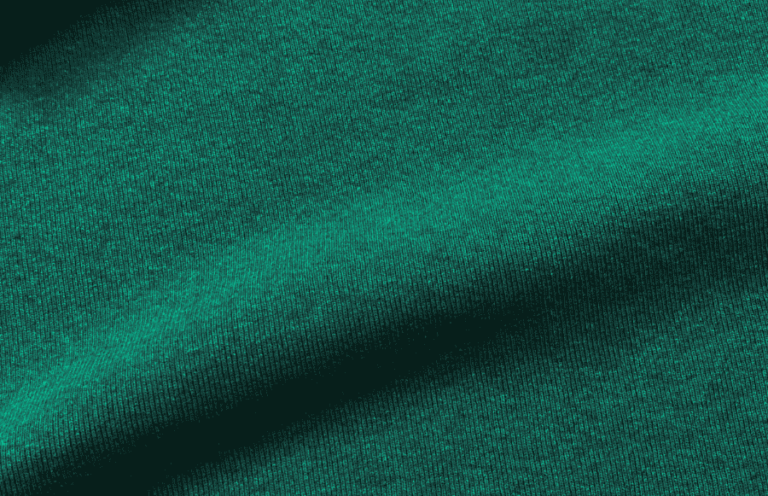

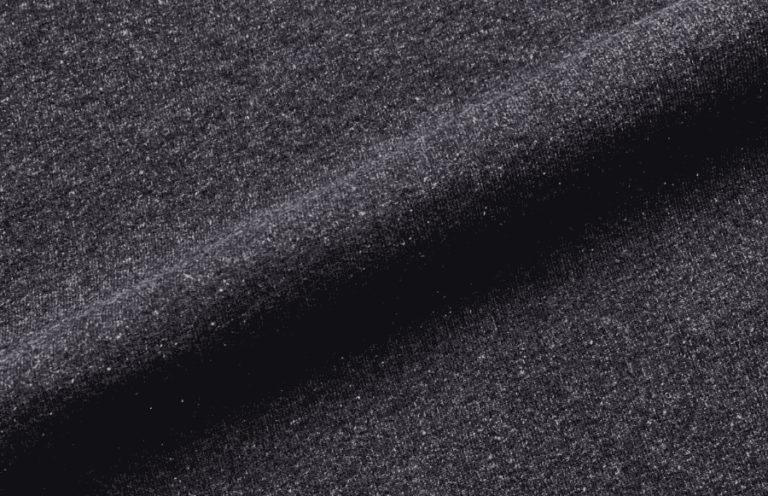

Types of Recycled Cotton-Polyester Blend Fabric

Available in a range of colors and textures, all GRS certified!

Why Recycled fabric is the Best Choice

Have an idea in mind? We help you!

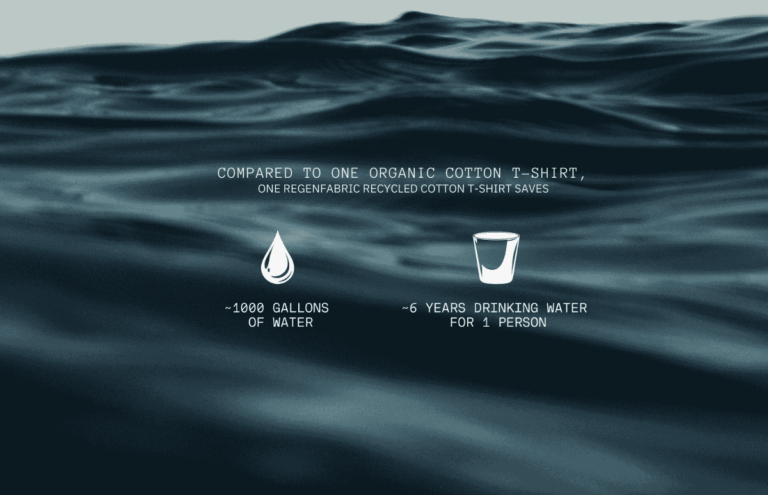

1. ECO

By using GRS-Certified recycled cotton /polyester fibers, Regenfabric delivers more colorfast and stable colors, avoids water-intensive post-dyeing, and shortens production lead time.

- Water & energy saving

- Streamlined process

2. High Performance

Regenfabric’s color penetrates the fiber, yielding excellent wash and light fastness with minimal fading over time.

- High wash & wear resistance

- Stable fabric performance

- Small Batch Flexibility

3. Cost Efficiency

Regenfabric (recycled cotton-poly blend) achieves approximately 10%-40% lower cost compared to traditional water-dyed fabric of equivalent quality

- Color before Spinning

- Elimination of dyeing costs

- Overall cost down by 10–40%

- Lifecycle cost benefits

4. CUSTOM aVAILABLE

Even for unique corporate or high-saturation colors, Regenfabric can meet the demand by adapting the process, effectively offering “no color limitations” to clients.

- Controllable whiteness

- unique “space-mixed” color effect

- weave-then-dye for Special Color

What can you get

Customizing your sustainable fabric can be easy. Leave it all to Regenfabric Ltd.

Boost Your Brand’s

Eco-Friendly Image

Sustainability isn’t just a buzzword; it’s a story your brand can own.

Share how your products are made from recycled materials, saving water and cutting CO₂ emissions. This isn’t just good for the earth—it’s good for business.

A compelling story builds trust, sparks loyalty, and makes your brand unforgettable.

solutions from recycled fabric manufacturer

Need a specific fabric weight or feel?

We offer a range of GSM options and can even develop custom weights or blends to match your exact requirements.

You get the precise material characteristics you need without compromise, saving you time on sourcing multiple vendors for different specs.

On-Time Delivery

We know delays can derail your production schedule.

We are ALL-IN ONE recycled fabric manufacture, Unlike suppliers who outsource parts of the process, we handle everything ourselves—from yarn blending and knitting, quality inspection, and final packing.

Our multi-line setup gives us flexibility to handle urgent and large-volume orders without compromising on lead time or quality.

Send The Recycled Fabric Plan

Start Your Customized Project

Guaranteed recycled fabric quality

At Regenfabric Ltd, you are not just a spectator, but a key participant in the process.

We invite you to visit our factory and see first-hand how each fabric is created.

From yarn blending to final rolls, we conduct multi-stage inspections for GSM accuracy, shrinkage, colorfastness, and handfeel.

Every batch goes through rigorous quality control, including colorfastness testing and durability checks. The result? Consistent, vibrant fabrics that meet your standards before they ship, so you never have to worry about quality complaints or returns.

Expertise in Color-Spun

Say goodbye to fabrics that fade or bleed.

We’ve refined our yarn-dyed / color-spun techniques over years of production—delivering stable, even colors that won’t fade or bleed.

Because the color is locked in at the fiber stage, not post-dyeing, you get more eco-friendly fabric with excellent colorfastness and shade consistency, even in repeated washes.

Competitive Prices for recycled fabric

Worried about costs? Don’t be.

Eco-friendly doesn’t have to mean expensive. Our sustainable fabrics can save you 10-50% compared to traditional options, letting you boost your brand’s image without breaking the bank. It’s a win-win: you look good, and your budget stays happy.

Get up close with our high quality customized process

See to Believe!

Combine colored and/or undyed fibers in specific ratios to achieve the desired color and properties. This step ensures a consistent mix before spinning.

Reach us

- We will contact within 12 hours.

- Don't worry, we hate spam too!

FAQ

MOQs depend on the specific fabric type and finish. We typically offer flexible starting points to accommodate both emerging and established brands.

Yes. Our manufacturing processes and materials undergo third-party audits to ensure GRS compliance for recycled content, social responsibility, and environmental practices.

Absolutely. We offer a wide range of color options and can collaborate on specific blends to match your brand’s aesthetic and performance requirements.

Lead times vary by order size and customization. On average, standard production ranges from 20 to 45 days. Rush options are available for an additional fee, potentially reducing lead times to 10-15 days depending on current production capacity.

Simply fill out our online form or contact us directly. Provide your requirements, and we’ll arrange a quote and sample package.

The price of custom recycled fabric is affected by material selection,Knit Construction Complexity and quantity.

We will work closely with you to provide a transparent pricing structure based on your specific requirements and budget.