Hi, I’m Leo, your sales manager at RegenFabric. Water’s a big deal—textiles guzzle tons of it. But what if we could save 140 tons per ton of fabric? That’s our color-spun magic, helping your brand shine sustainably.

Snippet: Traditional dyeing uses up to 200 tons of water per ton of fabric. Our color-spun tech skips it, saving 140 tons—70% less! Perfect for brands that care about the planet.

Okay, water savings1 are cool, but there’s more to this story. Let’s unpack why our fabric’s a win for you.

How does color-spun fabric save so much water?

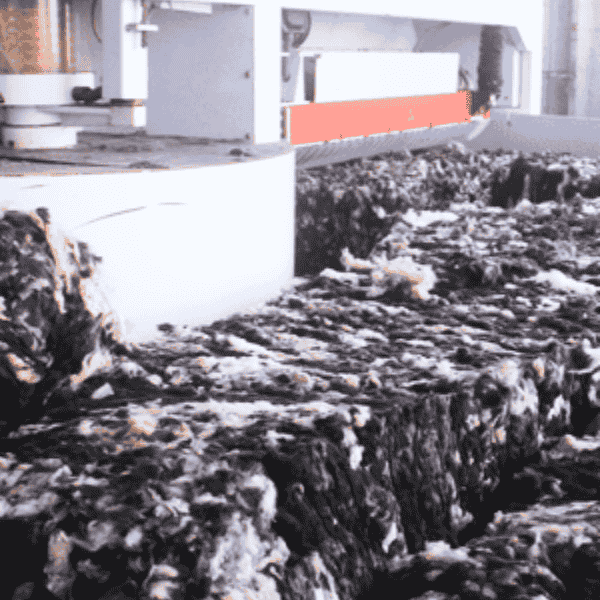

Picture this: traditional dyeing drowns fabric in water-heavy vats. Our color-spun trick? We weave "color" right into the yarn—no dyeing needed.

Snippet: By ditching dyeing, we save 140 tons of water per ton of fabric. Less water, less waste—simple, clean, and green.

Last year, I visited a factory using old-school dyeing—huge tanks, water everywhere. It hit me: this is nuts! At RegenFabric, we flip the script. We mix color into the yarn as it spins, so by the time it’s fabric, it’s ready to roll—no soaking required. That’s how we save 140 tons of water per ton. Crazy, right? An Olympic pool holds 2,500 tons—our daily 17-ton output saves enough to fill over 50 pools a year!

But it’s not just numbers. Less dyeing means less dirty water dumped into rivers. Traditional methods can use 30-150 liters per kilo of fabric—that’s 30-150 tons per ton, just for dyeing. We cut that to zero for that step. Sure, we use some water elsewhere, but the big savings come here. Imagine your brand telling customers, “Hey, we’re keeping water clean!” That’s a story worth sharing.

Water Usage Comparison

| Method | Water for Dyeing (tons/ton) |

|---|---|

| Traditional | 30-150 |

| Color-Spun | 0 |

Think about it: fewer pre-treatments like bleaching too. It’s like skipping the dishes before dinner—less mess, less fuss.

What else makes this fabric eco-friendly?

Water’s just the start. Our color-spun fabric2 slashes chemicals and energy use, making it a green dream for your brand.

Snippet: We cut chemical use by 80% and save energy—no dyeing, no heating. Your carbon footprint shrinks fast.

Dyeing’s a chemical soup—nasty stuff to fix colors. I once spilled dye on my shirt; it didn’t budge for weeks! We skip that, cutting chemical use by 80%. Cleaner production, fewer headaches. And energy? Heating dye vats is like boiling an ocean. We don’t, so we save 445 kg of CO2 per ton. With 17 tons daily, that’s 7.5 tons of CO2 less—daily! Picture 1.6 cars off the road every day.

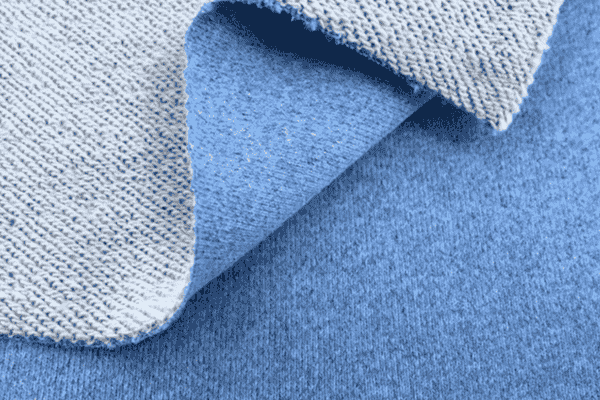

Plus, our fabric’s 100% recycled—rPET and cotton from old bottles and scraps. It’s like giving trash a second life. Your customers will love that. Pair it with our GRS certification, and you’ve got a transparent, planet-friendly supply chain. Ever wonder how to stand out? This is it—sustainability that’s real, not just talk.

Environmental Wins

| Factor | Traditional | Color-Spun |

|---|---|---|

| Chemicals | High | 80% less |

| Energy | High | Way lower |

| CO2 (per ton) | High | 445 kg less |

Is the quality as good as traditional fabric?

You’re thinking, “Sounds great, Leo, but does it hold up?” Yep—our fabric’s tough, soft, and ready for anything.

Snippet: Air-jet spinning makes our fabric strong and smooth. It’s perfect for T-shirts or sweatshirts—durability you can feel.

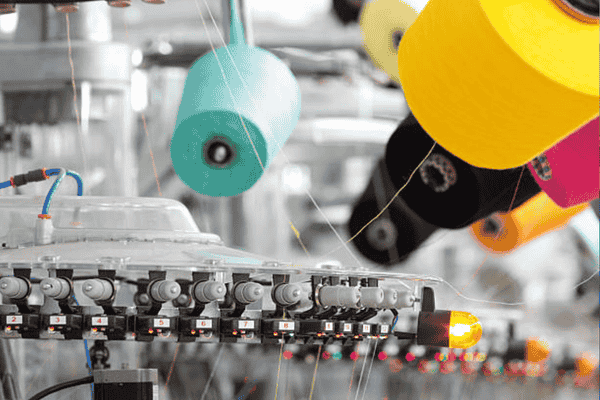

I wore one of our color-spun T-shirts hiking last summer—rough trails, sweaty days, tons of washes. Still looks brand new! We use fancy air-jet machines (think Titan K80) to spin yarn that’s even and strong—20% tougher than regular stuff. No pilling, no tearing. And the color? Baked into the yarn, so it doesn’t fade like dyed fabric. Your customers won’t toss these after a season.

A U.S. brand switched to our T-shirt fabric—bam, 30% more happy reviews. “Durable,” they said. “Colors pop!” Quality matters, and we deliver. Whether it’s sweatshirts (180 cm wide, 210-320 GSM) or T-shirts (140-300 GSM), it’s versatile and comfy. I’d bet my coffee on it—and I love my coffee.

Why It Works

The secret? Air-jet tech. It’s like spinning silk with steel strength. Your products last, and that builds trust.

How does this save me money?

Sustainability’s awesome, but your wallet matters too. Our fabric cuts costs without cutting corners.

Snippet: No dyeing means 10-15% cheaper fabric. Faster production—20-30% quicker—gets your goods out fast.

Dyeing’s pricey—machines, chemicals, energy. We skip it, so you save 10-15% on every order. Last month, a fast-fashion client cut two weeks off their timeline with our 20-30% faster process. Sales jumped 25%! Time’s money, right? Less water, less energy—it all adds up.

- Cash Saved: 10-15% lower prices.

- Speed Boost: 20-30% faster delivery.

- Bonus: Eco-vibes that sell.

Jane from EcoFashion Inc. told me, “Leo, it’s a no-brainer—cheaper, greener, better.” She’s right. You get quality fabric, a leaner budget, and a story that hooks customers. Who doesn’t love a win-win?

Real-World Payoff

Faster turnarounds mean you beat trends. Lower costs let you price smart. It’s practical magic.

Conclusion

I’m proud of our color-spun fabric2—it saves 140 tons of water per ton, cuts costs, and keeps quality high. Want to make your brand greener and smarter? Email me at sales@regenfabric.com—let’s chat!