Stretch fabrics are everywhere, from jeans to activewear. But mixing stretch fibers like spandex1 with cotton makes recycling tricky.

Yes, recycled cotton can be used with spandex in stretch fabrics, but making them truly circular faces challenges in blending, performance, and end-of-life recycling, requiring smart design and new technologies in 2025.

At regenFabrics, we see the future of textiles in circularity. My name is Leo, I am Sales Manager here. Brands want sustainable fabrics, and they also need stretch for comfort and fit. So, the question of recycled cotton2 with spandex comes up a lot. Can these two fibers work together, not just in a shirt, but in a system where they can be recycled again later? It is a complex area with big steps forward happening right now. Let's look at the possibilities and the challenges.

Why Blend Recycled Cotton with Spandex in the First Place?

Why do brands even mix cotton, recycled or new, with spandex? It is all about giving clothes that needed stretch.

Blending cotton with spandex gives fabrics comfort, fit, and shape-holding abilities that 100% cotton lacks, making it popular for everyday clothing like jeans and activewear.

Cotton is loved for its soft feel, how it breathes, and how it takes dye. But 100% cotton fabric does not stretch much. It can also lose its shape over time, especially with movement. This is why spandex, also known as elastane, was created and is used so widely. Spandex is a man-made elastic fiber. Adding even a small amount of spandex to cotton fabric gives it stretch and recovery – meaning it stretches when you move and goes back to its original shape afterward. This is essential for things like tight jeans, comfortable leggings, or activewear that needs to move with the body. Without spandex, these clothes would be stiff and not fit well. So, the reason for blending is simple: combine the comfort of cotton with the needed function of stretch. When brands want to use recycled cotton to be more sustainable, they still need that stretch function for many product types. This means finding ways to blend recycled cotton with spandex (or other elastic fibers) effectively. It is not just about making the fabric stretch, but doing it in a way that the recycled cotton fibers can still be used well in the blend, even if they are shorter than new cotton fibers. This requires careful fiber selection and spinning techniques. Using recycled cotton in these blends helps lower the environmental effect compared to using all new cotton, as it reduces the need for virgin cotton farming. So, blending recycled cotton with spandex allows brands to make popular stretch products more sustainable, meeting consumer demand for both comfort and environmental care.

Can Recycled Cotton Be Used in Performance Blends with Spandex?

Can you make fabrics for activewear or other high-stretch needs using recycled cotton and spandex? Yes, but it requires smart engineering.

Yes, recycled cotton can be used in performance blends with spandex, but achieving needed stretch and recovery requires careful blend ratios, specific yarn spinning techniques, and sometimes using advanced elastic fibers.

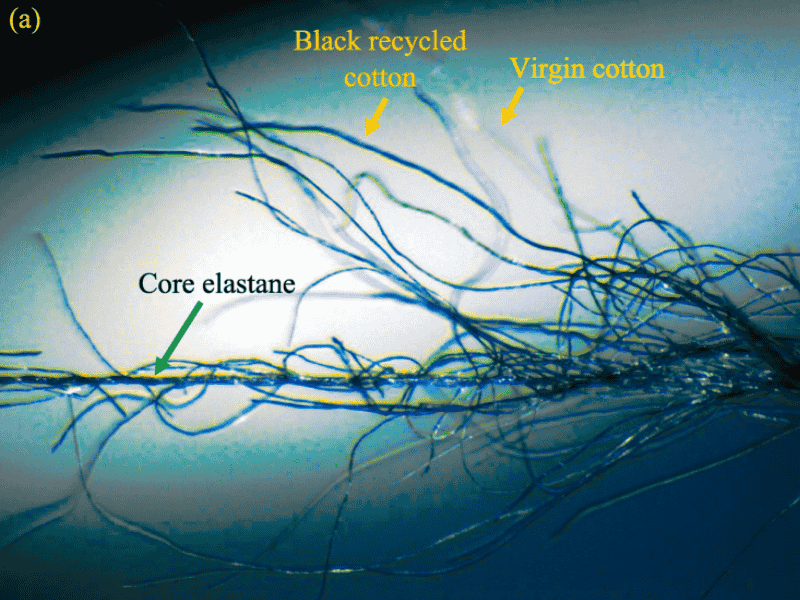

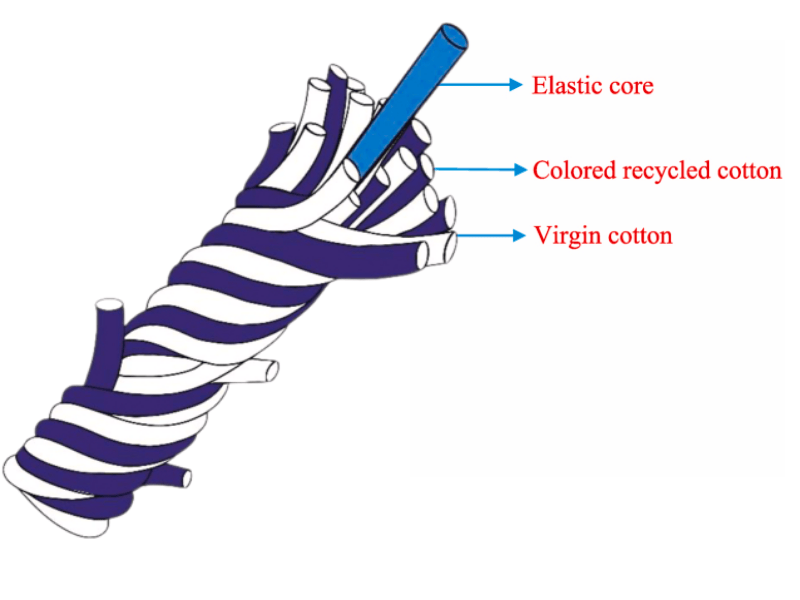

Making performance fabrics with recycled cotton and spandex is possible, but it is more complex than simple blends. Performance fabrics, like those used in activewear, often need high stretch (maybe 20% to 60% or even more) and very good recovery (the ability to snap back to shape quickly). Standard mechanical recycled cotton, with its shorter, weaker fibers, can make this hard. If you just mix short recycled cotton fibers with spandex and spin them together simply, the recycled cotton fibers might not hold onto the spandex core well. This can lead to lower stretch, poor recovery, and the cotton fibers coming out (pilling). To overcome this, specific yarn spinning methods are used. Core-spun yarns are very common. In core spinning, a core of spandex fiber is covered by a sheath of cotton fibers (recycled or new). This keeps the spandex in the center, giving the yarn its stretch, while the cotton on the outside provides the look and feel of cotton fabric. Dual-core spinning is an even more advanced type, using two core fibers for better strength and stretch control. Using these techniques allows us to make yarns where the recycled cotton fiber wraps around the spandex core, letting brands use recycled cotton while still getting the stretch needed for performance wear. The percentage of recycled cotton you can use depends heavily on the type of recycled cotton (pre-consumer often works better than post-consumer mechanical due to fiber length) and the blend. While achieving very high stretch (like 60%) with high percentages of mechanical recycled cotton (>25-30%) can be difficult, blends with 10% to 60% recycled content are being made and tested. For example, achieving moderate stretch might be possible with 20-30% mechanical recycled cotton in a core-spun yarn. For higher stretch or better recovery, using chemical recycled cotton (which has better fiber quality) or advanced elastic fibers like elasterell-p or certain types of Lycra can help. Elasterell-p is a type of polyester-based stretch fiber that can sometimes be easier to work with or recycle later than traditional spandex. Brands need to test these blends carefully to ensure they meet their specific stretch and recovery benchmarks for their product's end use. It is about using the right technology and fiber mix to make recycled cotton play well with stretch demands.

Fiber Compatibility & Proven Spinning Routes (core‑spun, dual‑core, elasterell‑p)

Mixing recycled cotton with stretch fibers requires careful fiber selection and yarn making. Mechanical recycled cotton's short fibers are harder to use with stretch than new cotton. Proven spinning methods like core-spun and dual-core wrap cotton fibers around a spandex or elasterell-p core, giving stretch and durability. Elasterell-p is a type of stretch fiber sometimes used as an alternative to traditional spandex.

Stretch‑and‑Recovery Benchmarks: What 10‑60 % Recycled Content Looks Like

The stretch performance of fabrics with recycled cotton and spandex varies based on the blend and construction. While high stretch (e.g., 40-60%) is easier to get with lower recycled cotton percentages or higher quality recycled fibers (like chemical), blends with 10-30% mechanical recycled cotton in core-spun yarns can still offer useful stretch for many applications like comfortable jeans or casual knits. Reaching the highest stretch levels (like 60%) with large amounts (>30-40%) of mechanical recycled cotton is challenging and often needs special yarn or fabric structures or blending with stronger fibers like recycled polyester alongside the elastic fiber.

Case Studies: Lycra T400 EcoMade, 60 % Recycled‑Cotton Core Yarn & More

Looking at real examples helps show what is possible. Brands and fiber makers are working on innovative recycled cotton stretch solutions.

Examples like trials with Lycra T400 EcoMade, core yarns using 60% recycled cotton in the sheath, and other projects show that high-recycled content stretch fabrics are becoming a reality through new technologies and collaborations.

Seeing is believing, especially when talking about new fabric types. Several companies are pushing the limits of recycled cotton stretch. One area of work involves new types of elastic fibers that are more sustainable or easier to recycle later. Lycra T400 EcoMade, for instance, is a type of stretch fiber that includes recycled content, often PET bottles. While not recycled cotton itself, trials blending Lycra T400 EcoMade with cotton (potentially recycled cotton in the future) show efforts to make the stretch component itself more sustainable. More directly related to recycled cotton, we see progress in making core-spun yarns with high amounts of recycled cotton in the outer part (the sheath). Some examples show successful trials producing core yarns where up to 60% of the cotton part is recycled cotton, wrapped around an elastic core. Achieving 60% recycled cotton in the sheath of a core-spun yarn for stretch fabric is a significant step. It allows brands to make a strong sustainability claim about the cotton content while still getting the stretch needed for items like denim or knitwear. These developments are often the result of close work between yarn spinners (like those using advanced air-jet spinning), fiber producers (making the elastic core and recycled cotton fibers), and fabric makers. These case studies are proving that the technical problems of mixing short recycled cotton fibers with elastic cores can be overcome with the right technology and knowledge. While not every high-recycled content stretch fabric is ready for mass market yet, these trials show a clear roadmap. For brands, these cases mean that reaching sustainability goals by using significant amounts of recycled cotton in stretch products is becoming a more real option. Working with suppliers who are involved in these types of developments, like regenFabrics with our experience in recycled blends and air-jet spinning, can help brands access these newer, more circular stretch fabric solutions.

Can You Mix Spandex with Cotton — and Still Recycle Later?

You want stretch now, but you also want to recycle later. Is it possible to design a cotton/spandex product today that can be recycled at the end of its life?

Mixing spandex with cotton makes recycling later difficult with current widespread technologies. However, designing products with specific fiber types and lower elastane content can help enable future recycling using upcoming separation technologies.

This is where "design for recycling" becomes very important. If brands and designers think about the end-of-life of a product right from the start, they can make choices that make recycling possible later, even for complex blends like cotton and spandex. As of 2025, recycling cotton/elastane blends back into high-quality textile fibers is hard. But by making smart design choices now, brands can make their products "recycling-ready" for the new separation technologies that are being developed. One key guideline is related to the amount of elastane used. Many experts recommend using ≤5% elastane3 in cotton blends if you want the fabric to be potentially recyclable in future chemical recycling systems. Higher amounts of elastane make the separation process much harder and more expensive. Another idea is to consider melt-spin alternatives or special types of elastic fibers. Traditional spandex is often hard to separate or breaks down badly in some recycling processes. Newer elastic fibers, or those made with different chemistries (like some types of polyester-based stretch fibers or TPEs), might be more compatible with chemical recycling processes designed to recover cotton cellulose. For example, fibers like XLance are special elastic fibers made by Kuraray that are chlorine resistant and stable, which might make them behave differently in certain chemical recycling processes compared to standard spandex. The goal is to use elastic fibers that can either be easily separated from the cotton or can be processed along with the cotton cellulose in a chemical recycling system without causing problems or lowering the quality of the new fiber. Brands need to talk with their fiber and fabric suppliers about these design choices. By choosing specific fiber types, limiting the percentage of elastic fiber, and avoiding complex structures or harmful finishes, brands can help ensure that the stretch fabrics they make today can truly become part of a circular system tomorrow, when the new recycling technologies are ready on a larger scale. It is about building recycling into the product design from the beginning.

Design‑for‑Recycling Guidelines (≤5 % Elastane, Melt‑spin Alternatives, XLance)

To help make cotton/elastane fabrics recyclable later, design choices are key. Guidelines include using ≤5% elastane, exploring elastic fibers that can be melt-spun or are designed for recycling (like certain polyester-based stretch or XLance), and simplifying fabric structures. These choices make it easier for future chemical recycling processes to separate or handle the different fiber types.

Quality‑Control Tests for Circular Stretch Fabrics

Even with recycled content, fabrics must perform. For circular stretch fabrics, quality tests are crucial. These include tests for stretch percentage, recovery (how well it goes back to shape), strength (tensile and tear), pilling (forming fiber balls), and colorfastness. Brands need to set clear standards for these tests and ensure suppliers meet them, proving that sustainability does not lower quality.

Roadmap to Commercialization (2025‑2030)

What does the future look like for recycled cotton stretch fabrics? We expect big steps forward between now and 2030.

Between 2025 and 2030, we expect significant progress in commercializing chemical recycling technologies for cotton/elastane blends, driven by new regulations, increased investment, and growing brand demand for circular solutions.

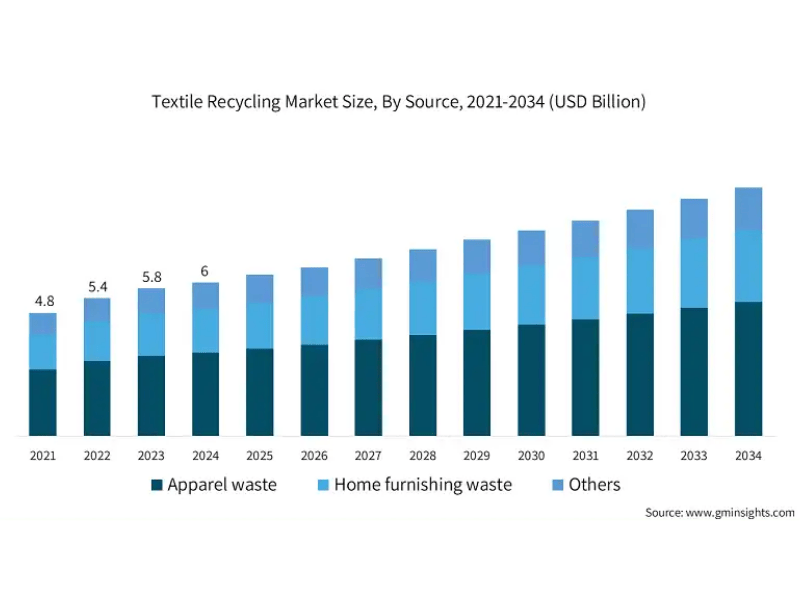

The period from 2025 to 2030 is crucial for the future of recycled cotton, especially in stretch fabrics. We are at a point where the technical pieces are starting to come together, and market and government forces are pushing for change. Currently, less than 1% of textile waste globally is truly recycled back into new fibers ("fiber-to-fiber" recycling). This number is expected to grow significantly, with some predictions seeing potential for 18-26% fiber-to-fiber recycling by 2030. This growth will largely depend on scaling up new technologies. Chemical recycling methods that can separate fibers in blends, like those using selective dissolution for cotton and elastane, are key parts of this roadmap. More pilot plants are expected to become larger, commercial-scale factories during this time. This will increase the supply of higher-quality recycled cotton fiber that can be used in more demanding applications like stretch fabrics. Policy and regulations are big drivers. The EU Waste Framework Directive requiring separate textile collection by 2025 is just one example. We expect more rules globally, including Extended Producer Responsibility (EPR) bills (like some being discussed in the U.S.) that make brands responsible for the end-of-life of their products. These rules will create a stronger market need for circular textiles and push investment in recycling infrastructure and technology. Brand commitment is also vital. More brands are setting recycled content goals and looking for truly circular supply chains. This demand encourages suppliers and recyclers to invest in new capabilities. For brands, the roadmap means: by 2030, sourcing higher percentages of recycled cotton for stretch fabrics should be more possible and cost-effective. Sourcing & Certification Checklist (GRS, RCS) will become even more important to prove recycled content and responsible practices. Brands will need to ask suppliers tough questions about their recycling partners and chain of custody. A Cost–Benefit Model vs. Virgin Cotton/Elastane will show that while initial investment in new processes might be needed, using recycled materials can offer cost savings in raw materials over time (e.g., switching to blends with high recycled content might offer cost benefits compared to virgin fibers, as some studies suggest). It also offers huge benefits for brand reputation and meeting future regulations.

Sourcing & Certification Checklist (GRS, RCS)

Getting GRS or RCS certified4 recycled cotton stretch fabrics means checking your supply chain carefully. What should brands look for and ask suppliers?

Brands should check if suppliers and their partners are GRS or RCS certified for recycled content, ask for Transaction Certificates to track material flow, verify social and environmental compliance audits, and confirm chemical management practices to ensure ethical and verifiable sourcing.

Sourcing truly certified recycled cotton stretch fabrics requires diligence. As GRS certification covers the entire supply chain, brands need to ensure every company handling the recycled material, from the fiber recycler to the fabric mill and garment maker, is certified. Here is a checklist for brands:

- Supplier Certification: Ask your fabric supplier (like regenFabrics) if they are GRS or RCS certified. Also, ask if their upstream suppliers (the yarn spinner, the recycler who made the fiber) are certified.

- Scope Certificates: Ask to see copies of the GRS or RCS Scope Certificates for your supplier and their relevant partners. Check that the certificates are current and cover the materials and processes you are buying.

- Transaction Certificates: For each shipment of recycled material, ask for a Transaction Certificate (TC). This document tracks the specific batch of recycled material as it moves through the certified supply chain, from one certified company to the next. It is proof of the chain of custody.

- Recycled Content Claim: Confirm the supplier can provide a clear GRS or RCS claim stating the type (pre- or post-consumer) and percentage of recycled content in the fabric.

- Social & Environmental Compliance (for GRS): If aiming for GRS, ask about the social and environmental audit results for the facilities. Ensure they meet GRS requirements for labor practices, water/energy use, waste, etc.

- Chemical Management (for GRS): For GRS, ask about their chemical management system and if they avoid restricted chemicals listed in the GRS standard.

- Design for Recycling: Discuss with your supplier how the fabric is designed. Does it use fibers that can be separated later? Is the elastane content low enough for future recycling?

Working with experienced and certified suppliers like regenFabrics, who understand these requirements and can provide the needed documentation, makes the sourcing process much smoother for brands committed to verifiable sustainability. We can guide brands on how our GRS-certified fabrics fit into their certification goals.

While initial costs for some advanced recycled cotton or chemical recycling processes can be higher, using mechanical recycled cotton blends often offers cost savings compared to virgin cotton/elastane, alongside significant environmental and brand value benefits.

Table 1. Cost to Manufacture 1 kg of 16 Ne (36.9 Tex) Elastic Recycled Cotton/Virgin Cotton Yarn in Compact Spinning

| Cost Components | 0% Recycled | 10% Recycled | 20% Recycled | 30% Recycled | 40% Recycled | 50% Recycled | 60% Recycled |

|---|---|---|---|---|---|---|---|

| Ratio of Recycled Cotton : Virgin Cotton : Elastane in Yarn | 0 : 96.38 : 3.62 | 10 : 86.38 : 3.62 | 20 : 76.38 : 3.62 | 30 : 66.38 : 3.62 | 40 : 56.38 : 3.62 | 50 : 46.38 : 3.62 | 60 : 36.38 : 3.62 |

| Virgin Cotton (2.2 USD/kg) | 2.12 | 1.90 | 1.68 | 1.46 | 1.24 | 1.02 | 0.80 |

| Recycled Cotton (1.36 USD/kg) | 0 | 0.14 | 0.27 | 0.41 | 0.54 | 0.68 | 0.82 |

| Elastane (4.38 USD/kg) | 0.158 | 0.158 | 0.158 | 0.158 | 0.158 | 0.158 | 0.158 |

| Total Raw Materials Cost per kg Yarn | 2.278 | 2.198 | 2.108 | 2.028 | 1.938 | 1.860 | 1.780 |

| Manufacturing Overhead per kg Yarn | 0.94 | 0.95 | 0.955 | 0.965 | 0.97 | 0.98 | 0.99 |

| Total Cost of Yarn per kg Yarn | 3.218 | 3.148 | 3.063 | 2.993 | 2.908 | 2.838 | 2.768 |

Notes:

- The current price of recycled cotton in Bangladesh is used. The price of recycled fiber varies over time with market demand.

- Manufacturing overhead (production cost including electricity & labor cost) slightly increases with the increase of recycled cotton percentage in yarn, as the speed of the ring frame must be reduced to control end-breakage.

When brands compare recycled cotton stretch fabrics to traditional virgin cotton/elastane, they need to look beyond just the direct material price. The cost picture is changing. For mechanical recycled cotton, the raw material (textile waste) can sometimes be cheaper than virgin cotton fiber, especially pre-consumer waste. However, the processing into usable fiber adds cost. Blending mechanical recycled cotton with recycled polyester (rPET) and spandex/elastane, like in our TC/CVC blends, can offer competitive pricing compared to blends using virgin cotton and virgin polyester/spandex. For example, some estimates suggest that using a blend with a high percentage (e.g., 60%) of mechanical recycled cotton in a core yarn can cut the raw material cost by around 14% compared to a similar yarn made entirely from virgin fibers. This shows a clear potential for cost savings with mechanical recycled cotton blends5. Chemical recycled cotton is currently more expensive than both mechanical recycled cotton and often virgin cotton. This is because the technology is newer, investment costs are high, and production is not yet at a large scale. However, as chemical recycling scales up by 2030, its cost is expected to decrease. The benefits of using recycled content also include non-price factors. Environmental benefits (lower water, energy, chemical use, less waste) are significant and can be reported in ESG goals. Brand value and consumer appeal are growing, as consumers increasingly prefer sustainable products. This can lead to higher sales or allow for a price premium. Meeting future regulations (like EPR) will be necessary, and already using recycled content prepares brands for this, potentially avoiding future costs or fines. Supplier relationships with innovative recycled fabric makers like regenFabrics can also lead to long-term partnerships and access to future circular technologies. So, a full cost-benefit model includes not just the price per kilogram or meter, but also the environmental savings, market advantages, and future compliance benefits. For many applications, especially using mechanical recycled cotton blends, the overall picture shows clear benefits.

Supplier Questions to Ask Before You Place an Order

Before you buy recycled cotton stretch fabrics, you need to ask your supplier the right questions. What should be on your list?

Before ordering, ask suppliers about the recycled cotton source (pre/post-consumer, mechanical/chemical), certification details (GRS/RCS Scope and Transaction Certificates), blend composition and performance data, design-for-recycling aspects, and their experience with circular textile programs.

Choosing the right supplier for recycled cotton stretch fabrics is key to getting quality and ensuring the sustainability claims are real. As Sales Manager at regenFabrics, I help brands navigate these questions. Here are some important things to ask:

- Source of Recycled Cotton: Ask where their recycled cotton comes from. Is it pre-consumer or post-consumer waste? Is it from mechanical or chemical recycling? This affects fiber quality and environmental impact.

- Other Fibers in Blend: If it is a blend (like with spandex or polyester), ask about the source of those fibers too. Is the polyester recycled (rPET)? What type of elastic fiber is used (spandex, elasterell-p, XLance)?

- Certification: Are they GRS or RCS certified? Ask for their Scope Certificate to see what materials and processes are covered. Request Transaction Certificates for your specific order to prove chain of custody.

- Recycled Content Percentage: Get a clear statement on the percentage of recycled content, broken down by fiber type (e.g., 30% mechanical recycled cotton, 40% rPET, 30% virgin cotton).

- Performance Data: Ask for test reports on key performance areas, especially for stretch fabrics. This includes stretch percentage, recovery, tensile strength (like ISO 2062 data), pilling, and colorfastness. How does the recycled blend compare to a similar fabric made with virgin fibers?

- Spinning Method: For blends with mechanical recycled cotton, ask about the spinning method (e.g., ring, open-end, air-jet, core-spun, dual-core). This affects yarn quality and how it uses shorter fibers.

- Design for Recycling: Ask if the fabric is designed for recycling. What is the elastane percentage? Are the fibers easy to separate? Are there harmful finishes?

- Experience with Circularity: Does the supplier have experience working with brands on take-back programs or other circular initiatives? Can they help track materials or provide data for ESG reporting?

- Quality Control: What quality control steps do they have in place specifically for recycled materials?

Asking these questions helps you understand the fabric's true sustainability, quality, and recyclability. It ensures you are working with a supplier who is transparent and capable, which is what we aim for at regenFabrics.

Conclusion

Making circular stretch fabrics with recycled cotton is challenging but possible. Blending, smart design, and new recycling tech are key for a sustainable and stretchy future.

-

Learn how spandex enhances fabric performance, providing stretch and recovery, which is crucial for comfort in activewear and everyday clothing. ↩

-

Explore the advantages of recycled cotton in textiles, including sustainability and performance benefits, to understand its growing importance in the industry. ↩

-

Understanding the significance of ≤5% elastane can help brands design fabrics that are more recyclable, ensuring sustainability in fashion. ↩

-

Learning about GRS or RCS certification can help brands ensure their materials are responsibly sourced and meet sustainability standards.

Is using recycled cotton stretch fabrics more expensive? Looking at the full picture, there can be benefits beyond just the price per meter. ↩ -

Explore this link to understand how mechanical recycled cotton blends can offer cost savings and environmental benefits, enhancing your fabric choices. ↩