French terry feels "simple," but it often gets chosen wrong. That mistake can ruin fit, comfort, and cost. I use this guide to pick the right French terry fast.

French terry is a knit fabric with a smooth face and looped back. It stays breathable, holds shape better than jersey, and feels softer than many heavy knits. It is used for hoodies, joggers, tees, and sets.

I have handled many "fleece requests" that were actually French terry needs. That gap keeps showing up in sourcing talks, so I will break it down in plain steps, and I will keep it practical for real buying decisions.

What Is French Terry Fabric?

People call many fabrics "terry," and the wrong label gets used in sampling. That confusion leads to wrong GSM, wrong hand feel, and wasted time. I have seen this happen even in big programs.

French terry is a knit with a smooth outer surface and loops on the inner surface. The loops help moisture move, and the face stays clean for printing and branding. It sits between jersey and fleece in warmth and structure.

French terry is usually defined by its two-sided build. One side is made to look clean. The other side is made with loops that can absorb and release moisture. That is why French terry gets used in active and casual pieces. It is also why it feels less "hot" than fleece in many cases. In my work, the decision is often driven by three checks: skin feel, shape, and season range. A quick way to screen it is this table:

| Check point | What I look for | Why it matters |

|---|---|---|

| Face side | Smooth, even knit | Prints and embroidery sit better |

| Back side | Loops are even, not snaggy | Comfort and durability are protected |

| Recovery | Fabric returns after stretch | Cuffs and hems keep shape |

When recycled cotton and recycled polyester are blended, more stability is often added, and shrinkage risk can be reduced. In our recycled poly-cotton French terry, color-spun yarn is often used, so dyeing steps can be reduced, and a natural heather look can be delivered.

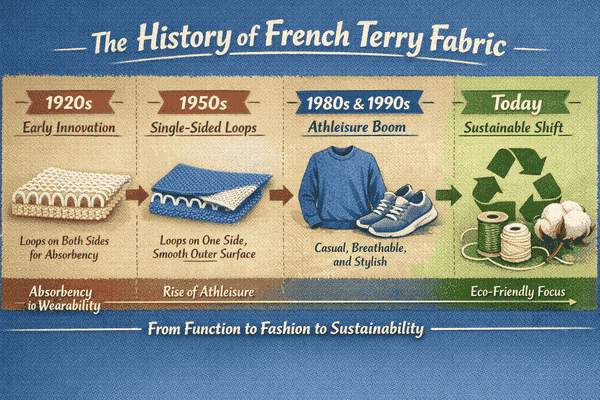

What Is the History of French Terry Fabric?

A fabric name can hide real structure. That happens with "terry" all the time. If the history is not understood, the fabric purpose can be misread.

The word "terry" is linked to older loop-making methods, and French terry evolved into a lighter terry style with loops on only one side. It became popular for casual and athletic wear once comfort and easy care were demanded at scale.

The early idea was simple: loops were created to add absorbency and comfort. Over time, the loop was kept on one side only, so a cleaner outer surface could be used for garments. That change is what made French terry more "wearable" than towel terry. In the 1980s and later, athleisure growth pushed demand for fabrics that could move, breathe, and still look neat. French terry fit that need. In my sourcing notes, French terry is often chosen when a brand wants a sweatshirt feel without heavy brushing. It is also chosen when the outside must stay clean for logos. Today, the same logic is still used, but the fiber story has changed. Recycled polyester and recycled cotton blends are now being used more, because sustainability targets are being set by more brands, and supply is getting more stable. That is why recycled French terry is being pushed into fast-moving fashion categories, not only premium loungewear.

How Is French Terry Fabric Made?

Many buyers ask for "loops inside" without asking how loops are controlled. That can cause pilling complaints later. I have seen that complaint show up after one season of wear.

French terry is made by knitting a structure where loops are formed on the back while the face stays smooth. Loops can be left as-is, brushed lightly, or flipped to the outside for a different look. Fiber blends and yarn type change stability and cost.

Loop control that decides performance

Loop size and density are set by machine settings and yarn choice. Longer loops can absorb more, but snag risk can rise. Shorter loops can feel cleaner and pill less, but absorbency can drop.

Yarn choice that changes the "base feel"

In recycled poly-cotton French terry, yarn can be made by air-jet spinning. In our case, color-spinning has been used, so fibers are blended by color before yarn is formed. That is why a natural mélange effect can be achieved without normal dyeing. It also means water, chemicals, and energy tied to dyeing can be reduced in many programs, and cost can be saved in a direct way.

| Manufacturing choice | What is changed | What I expect in fabric |

|---|---|---|

| Uncut loops | Loops kept intact | Breathable, balanced warmth |

| Light brushing | Loop tips softened | Softer hand, slightly warmer |

| Recycled poly-cotton blend | Fiber mix changed | Better stability, good durability |

In 2026, development work on air-jet spun recycled poly-cotton French terry for T-shirts and sweatshirts was carried out with a Japanese fast-fashion leader, and the fabric was built to feel thicker and more solid than many standard knits used in similar styles.

What Types of French Terry Fabric Are Common?

A buyer may say "French terry," but ten different fabrics can still be delivered. That gap creates price fights and quality disputes. I try to lock the type early.

French terry is commonly grouped by fiber content, GSM weight, and finish. Cotton, organic cotton, and cotton blends are common. Recycled blends are growing fast. GSM decides season use. Finish decides softness and look.

By fiber content

Cotton feels natural and breathable. Organic cotton is often chosen for brand story and skin comfort. Cotton + spandex is often used for stretch recovery. Cotton + polyester is often used for durability and lower shrink. Sustainable fabric blends1 can include recycled fibers, Tencel, hemp, and more. In my work, recycled cotton + recycled polyester is now asked for more often, because certifications and traceability are being requested more.

By weight (GSM)

| Category | GSM range | What I use it for |

|---|---|---|

| Lightweight | 171–230 | Summer tees, light hoodies |

| Midweight | 231–340 | Year-round sweat sets |

| Heavyweight | 341–450 | Winter hoodies, structured pieces |

| Ultra heavyweight | 450+ | Premium oversized and outer layers |

By finish

Standard, brushed, reverse, high-loop, and low-loop options exist. I often match finish to end use, because finish changes pilling risk and heat feel.

What Are 6 Common Uses for French Terry Fabric?

French terry gets used everywhere, but wrong GSM still gets ordered. Then returns happen. I try to map use to weight and finish first.

French terry is used for hoodies, sweatshirts, joggers, sweatpants, tees, shorts, light jackets, and athleisure sets2. GSM and loop finish decide comfort and season range, so they should be matched to the garment plan before bulk.

In bulk programs, French terry is often chosen because it balances comfort and structure. For hoodies, midweight and heavyweight are often picked, because shape is held and warmth is kept without extreme bulk. For joggers, midweight is often used, because knees and seat areas need support. For T-shirts, lightweight French terry can feel more premium than jersey, because the body feels thicker and the drape is controlled. Shorts can be made with summer-weight French terry to avoid fleece heat. Light jackets and cardigans can be made with heavier French terry when a neat surface is needed. Sets are a big trend driver, because matching tops and bottoms create repeat orders. In recycled poly-cotton French terry, the "mélange" color effect from color-spun yarn is often liked for sets, because a dyed flat color can look less rich.

For activewear applications, French terry offers the right balance of breathability and structure that performance-focused garments require.

| Garment | Suggested GSM | What I watch |

|---|---|---|

| Hoodie | 260–450 | Pilling, shrink, recovery |

| Jogger | 260–340 | Knee bagging, seam strength |

| Tee | 180–240 | Hand feel, face smoothness |

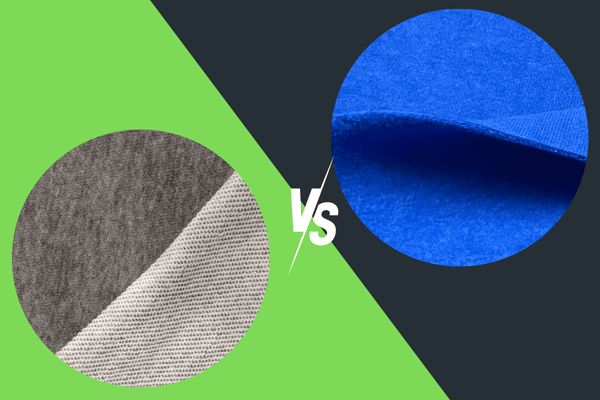

How Is French Terry Different From Fleece?

"Fleece" is requested when warmth is wanted, but breathability is forgotten. Then customers overheat. I have received that complaint in wear trials.

French terry has intact loops inside, so it stays more breathable and manages moisture better. Fleece is brushed to a fuzzy pile, so it traps more heat and feels warmer. French terry fits more seasons. Fleece fits colder seasons.

The key difference is the inside. French terry keeps loops. Fleece cuts and brushes loops into a pile. That pile holds heat. That is why fleece is often chosen for winter. French terry still warms, but air can move through the loop structure, so it often feels less "stuffy." In buying meetings, I often frame it like this:

| Feature | French terry | Fleece |

|---|---|---|

| Inside | Loops intact | Brushed fuzzy pile |

| Breathability | Higher | Lower |

| Warmth | Medium | High |

| Best use | Year-round layers | Cold-weather insulation |

Understanding these differences is essential when comparing knit fabric types3 for different applications and seasons.

In recycled poly-cotton French terry, durability is often improved versus pure cotton terry. That matters in cuffs and waistbands, because friction is high there. For brands selling fast-moving sweats, fewer returns are often achieved when fabric breathing and durability are balanced, not only warmth.

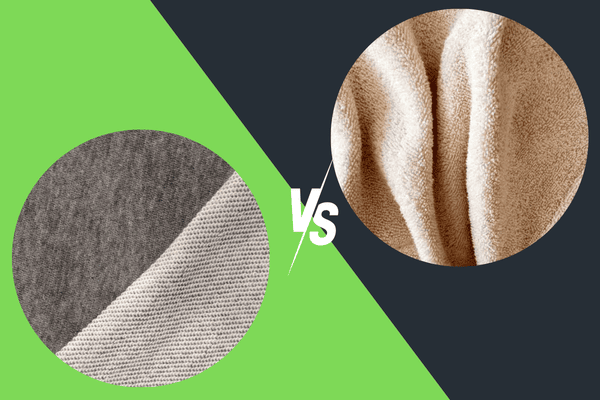

How Is French Terry Different From Terry Cloth?

Many people think towel terry and French terry are the same. Then a garment is made that feels like a bathrobe. That can kill the style.

French terry has loops on one side and a smooth face on the other. Terry cloth often has loops on both sides and is made for high absorbency. French terry is made for wearable comfort and cleaner appearance.

Both fabrics use loops, but the loop purpose changes. In terry cloth, loops are built for maximum water pickup. That is why towels and robes use it. The loops are often longer and looser. In French terry, loops are built for comfort and light moisture handling, and the face is kept smooth for garment looks. That is why French terry is used for streetwear and athleisure. I also watch snag risk. Terry cloth loops can catch more easily. French terry loops are often shorter and denser, so snagging is reduced.

| Fabric | Loop sides | Absorbency | Typical products |

|---|---|---|---|

| French terry | One side | Medium | Hoodies, joggers, tees |

| Terry cloth | Two sides (often) | High | Towels, robes, resortwear |

When recycled fibers are used in French terry, loop integrity must be controlled, because shorter recycled cotton fibers can increase fuzz if spinning and knitting are not controlled well. That is why yarn method and finishing control are checked carefully in my process.

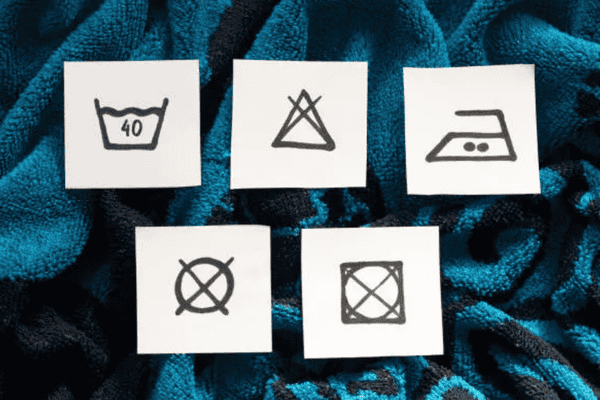

How Should French Terry Fabric Be Cared For?

Wrong care creates pilling, shrink, and dull surfaces. Then the fabric gets blamed. I prefer to set care rules early with buyers and factories.

French terry is best washed cold with gentle detergent, turned inside out, and dried low or air dried. High heat can damage blends and increase shrink. Pre-washing before cutting is recommended to control shrinkage and loop behavior.

French terry is a knit, so it can be stretched and distorted when heat and friction are high. Cold water is used to reduce shrink and keep fiber strength. Turning garments inside out reduces friction on the face and protects the loops. Overloading a washer increases rubbing, so pilling can rise. Drying on low heat or air drying helps loops stay intact. High heat can damage elastane in blends, and it can also set wrinkles. Storage is often done by folding, because hanging can stretch shoulders and hems. For stains, fast action is best. Cold water is used first, and harsh bleach is avoided, especially on colored fabrics. In color-spun recycled French terry, color is built from fiber blending, so harsh bleach can still damage fibers and create uneven look.

For comprehensive guidance on extending the life of your garments, explore fabric care best practices4 that apply across textile types.

I often use this simple checklist:

| Step | What is done | What is avoided |

|---|---|---|

| Wash | Cold, gentle cycle | Hot water, overload |

| Dry | Low tumble or air | High heat |

| Storage | Folded, dry place | Heavy hang time |

Is French Terry Good for Summer or Winter?

Some buyers think French terry is "only for hoodies." Others think it is "too hot." Both ideas are incomplete. Season fit is mainly a GSM question.

French terry can work in summer or winter, depending on GSM and finish. Lightweight French terry fits summer tees and shorts. Heavyweight French terry fits winter hoodies and layering. It is strongest in spring and fall because it stays breathable.

I treat French terry as a system, not one fabric. In summer, 171–230 gsm is often used. Air moves through the loops, so sweat can be managed, and the fabric does not feel as trapped as fleece. In winter, 341–450+ gsm is often used. Warmth is increased, but the surface can still look clean. For very cold climates, fleece can still win. For mild winters and indoor wear, heavyweight French terry can be enough. Personal body temperature matters. People who run hot often prefer French terry year-round, because breathability stays higher. People who run cold often layer it and switch to fleece in deep winter. Activity level matters too. French terry is often better for warm-ups and daily movement. For intense training, performance synthetics may be picked instead. When recycled poly-cotton is used, thickness and stability can be improved, so a more "solid" hand feel can be achieved without heavy brushing.

What Are the Advantages and Disadvantages of French Terry Fabric?

Every fabric has trade-offs, but they often get hidden in sales talk. Then complaints show up later. I prefer to state the trade-offs early.

French terry is breathable, comfortable, and versatile, and it holds shape better than jersey. It can pill on the loop side and can shrink if cotton-heavy and not pre-washed. It is medium warmth, so it is not extreme-weather fabric.

French terry is liked because it covers many use cases. It can be worn across seasons, and it can be washed easily. It can be used in sets and still look neat. It often keeps structure, so it does not look "thin" like some jerseys. But loop pilling can happen with friction. Velcro and rough surfaces can snag loops. Cotton-heavy versions can shrink more if pre-wash is skipped. French terry can also feel heavier than jersey, so it may not suit very light summer styling. Cost can be higher than basic jersey, because yarn and knitting structure can be more complex. In recycled blends, durability can be improved, but consistency must be controlled by good blending and spinning. In our dye-free color-spun approach, dyeing steps can be reduced, but color planning must be done earlier, because shade is built in fiber mixing, not added later.

| Topic | Advantage | Disadvantage |

|---|---|---|

| Comfort | Soft, not bulky | Loops can pill with friction |

| Look | Clean face, structured | Heavier than basic jersey |

| Care | Easy washing | Cotton versions can shrink |

How Do I Choose French Terry Fabric for Buying?

Choosing by "feel only" is risky. The same hand feel can hide big performance differences. I use a buying checklist to reduce surprises.

French terry should be chosen by end use, GSM, fiber content, stretch needs, and loop quality. Samples should be washed and tested before bulk. Matching rib should be checked for cuffs and waistbands to keep fit consistent.

I start with the garment plan. Hoodies usually need 231–450 gsm. Joggers often sit in 231–340 gsm. Tees often need 171–230 gsm. Then fiber is matched. If shrink and durability are concerns, cotton + polyester blends are often used. If stretch recovery is needed, 2–4% spandex can be added. If sustainability goals are strong, recycled cotton5 + recycled polyester can be used with GRS certification6, and color-spun options can be requested to reduce dyeing steps. Then loop and face quality is checked. The face should be smooth and even. The loops should be consistent and not loose. Stretch recovery is tested by pulling and letting go. Rib matching is checked, because a mismatch creates tight cuffs or wavy waistbands. I also order samples first and run a wash test, because real shrink and pilling show up fast in a controlled wash.

Understanding GSM weight specifications is crucial for making informed fabric selection decisions.

| Decision point | My simple rule | Quick test |

|---|---|---|

| GSM | Match season and structure | Weigh swatch or confirm spec |

| Fiber | Match comfort + durability | Check blend label and certs |

| Finish | Match softness vs breath | Feel loop side and rub test |

Where Can French Terry Fabric Be Bought?

Many sources sell French terry, but not all sources are good for repeat programs. The risk is supply drift. Then color and hand feel change between orders.

French terry can be bought from online retailers, local fabric stores, and wholesale suppliers. For brands and bulk programs, wholesale suppliers are often preferred because specs, certification, and re-order consistency can be managed with clear standards and sampling.

Where to buy French terry fabric<<

Retail channels can be great for small projects. They allow fast purchase and simple selection. Local stores allow touch and quick decision, but selection may be limited. Online retailers can offer many weights and blends, and sample services may be offered. But for brands, wholesale sourcing is often needed. MOQ will be required, but unit cost can be lower, and custom GSM and color can be offered. In recycled French terry, certification checks become important. Clear specs should be provided, including GSM, fiber content, width, shrink target, and color method. In my buyer conversations, I push for these "must-haves":

| Must-have item | Why I ask for it |

|---|---|

| GSM + width | Fit and yield are controlled |

| Fiber content + certs | Claims can be verified |

| Care and shrink guidance | Returns can be reduced |

| Sample option | Risk is reduced before bulk |

For our recycled poly-cotton French terry, color-spinning is used to reach heather tones that are hard to copy with normal dyeing. That can be a design advantage, not only a sustainability point.

What French Terry Works Best for Different Sewing Projects?

Project level matters, because French terry can shift, stretch, and curl at edges. That can frustrate beginners. I prefer to match project to stability.

Beginners do well with simple hoodies, joggers, and accessories using midweight French terry. Intermediate projects add zippers and pockets. Advanced projects use structure, lining, and color blocking. A stretch needle, longer stitch, and seam tests are key.

For beginner projects, stable midweight French terry is often easiest. A basic pullover hoodie works well because seam lines are simple and stretch is forgiving. Joggers with elastic waist are also friendly because fit is relaxed. Small items like headbands and scarves allow practice without large waste. For intermediate work, zippers and pockets are added, so shifting and stretching must be controlled. A walking foot can help. For advanced work, jackets and fitted dresses require more planning, because knit stretch must be managed and seam support may be needed. Needle choice matters. A ballpoint or stretch needle is often used (80/12 or 90/14). Stitch length is often set around 3–3.5 mm for flexibility. Polyester thread is often used for strength. I test seam stretch before final sewing. For hems, a twin needle can give a clean result. In recycled blends, seam strength is usually fine, but pilling and fuzz can rise if friction areas are not planned well, so reinforcement and better rib choices are often used.

| Skill level | Good projects | Fabric tip |

|---|---|---|

| Beginner | Hoodie, joggers, scarf | Midweight, low-loop |

| Intermediate | Zip hoodie, cuff joggers | Add walking foot |

| Advanced | Jacket, fitted styles | Stabilize key seams |

What Are the Most Common Questions About French Terry Fabric?

Small doubts can block buying decisions. That is normal. I keep a simple FAQ list so teams can move faster.

French terry is not always 100% cotton, it can resist wrinkles, it offers medium warmth, and it is often good for light to moderate activewear. Shrink is usually higher in cotton-heavy versions, and lower in blends. Ironing is possible on the smooth side with low to medium heat.

Quick answers I give buyers

- French terry can be 100% cotton, but blends are common for durability and recovery.

- Wrinkles are usually reduced because knit stretch is built in.

- Warmth is moderate. Heavier GSM gives more insulation, but it is still more breathable than fleece.

- Shrink is often around 3–5% for cotton-heavy, and around 1–3% for blends, but wash testing should be used as the real proof.

- Activewear use is common for warm-ups, yoga, and daily movement. For high-sweat training, performance synthetics may be preferred.

- Ironing can be done on the smooth side. Loops should not be pressed hard. Steam is often safer.

| Question | Short buying action |

|---|---|

| "Is it cotton?" | Ask for fiber % and certs |

| "Will it shrink?" | Run a wash test on swatch |

| "Will it pill?" | Rub test loops, check finish |

| "Is it stretchy?" | Check 2-way vs 4-way stretch |

When recycled poly-cotton French terry is selected, I also ask whether dyeing is needed. If color-spun yarn is used, dyeing steps can be reduced, and unique mélange tones can be reached that normal dyeing often fails to match in depth.

Conclusion

French terry is my go-to when comfort, breathability, and a clean face are needed. GSM, fiber blend, and loop finish should be matched to use, and samples should be tested before bulk.

References & Recommendations

-

FutureLearn, an authoritative educational platform (DA 92), provides comprehensive coverage of sustainable fabrics including recycled materials, Tencel, and hemp, aligning perfectly with French terry's sustainability evolution. ↩

-

Cosmo Sourcing specializes in textile sourcing with strong B2B expertise, explaining performance characteristics essential for athleisure and activewear applications of French terry fabrics. ↩

-

Longan Craft provides detailed technical information on knit fabric structures with clear comparisons of 17 knit types, helping readers understand how French terry differs from jersey, fleece, and other knits. ↩

-

TSI Apparel offers industry-standard fabric care guidelines backed by textile manufacturing expertise, covering washing, drying, and storage best practices to extend garment longevity. ↩

-

Recover™, a GRS-certified recycled fiber manufacturer, explains mechanical and chemical cotton recycling processes, fiber quality considerations, and environmental impact data supporting recycled cotton decisions. ↩

-

Textile Exchange is the official GRS administrator, providing authoritative guidance on certification requirements, chain of custody verification, and social/environmental standards for recycled textile production. ↩